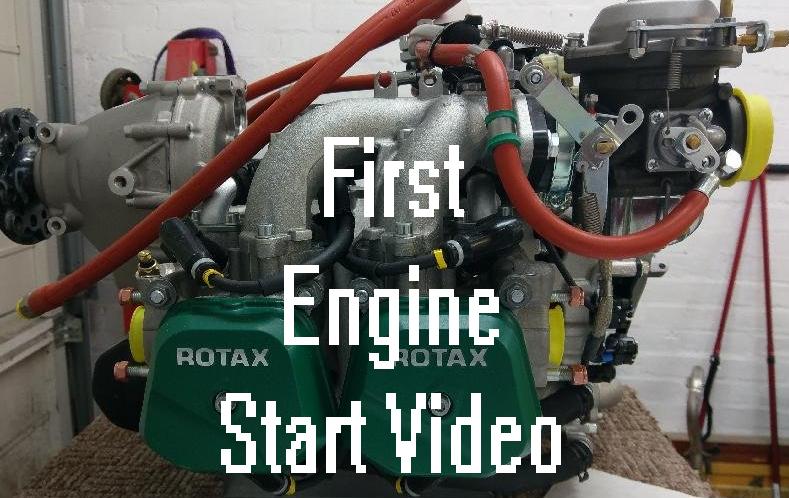

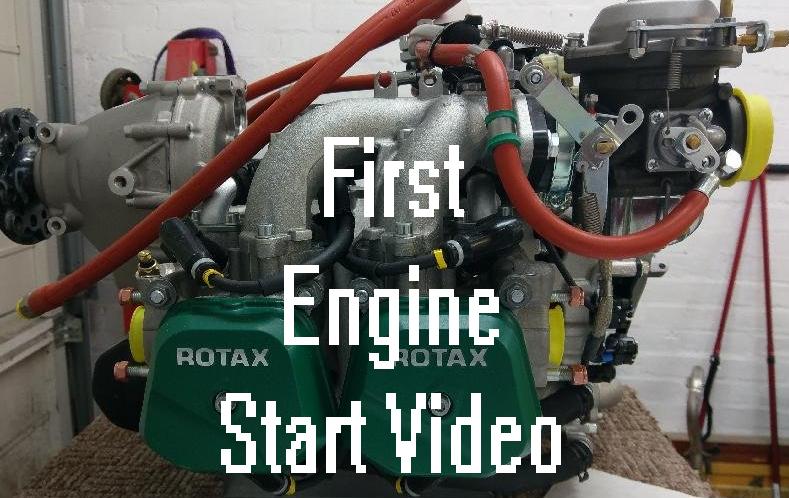

Now it was time to unbox and commission the engine. As delivered, it had been test run by the factory, then drained of liquids before despatch. The front undercarriage leg provided pasrt of the engine mounting frame, and the engine was attached to this, and a bracket that provided a stand off from the firewall. Fitting the radiator, oil cooler, and connecting up all the hoses, together with fitting the control cables for the throttle and choke was a fiddly job. Once the engine had been mounted, the propeller hub and blades were fitted. The propeller is a fixed pitch type, and enssuring the correct pitch angle of each blade was set correctly proved a challenging task. Once everything had been done, and double checked by my Inspector, the moment of truth arrived. Taking the fuselage out of the garage, positioning it on my drive, and securing the airframe by means of rope attached to the towbar of my car, it was time to fire her up. It can be seen by the above video that she started first time, and ran sweetly. The initial clicking that can be heard is the fuel pump, on this aaircraft Vans recommend keeping the electric fuel pump running constantly, but it doesn't half make a racket !